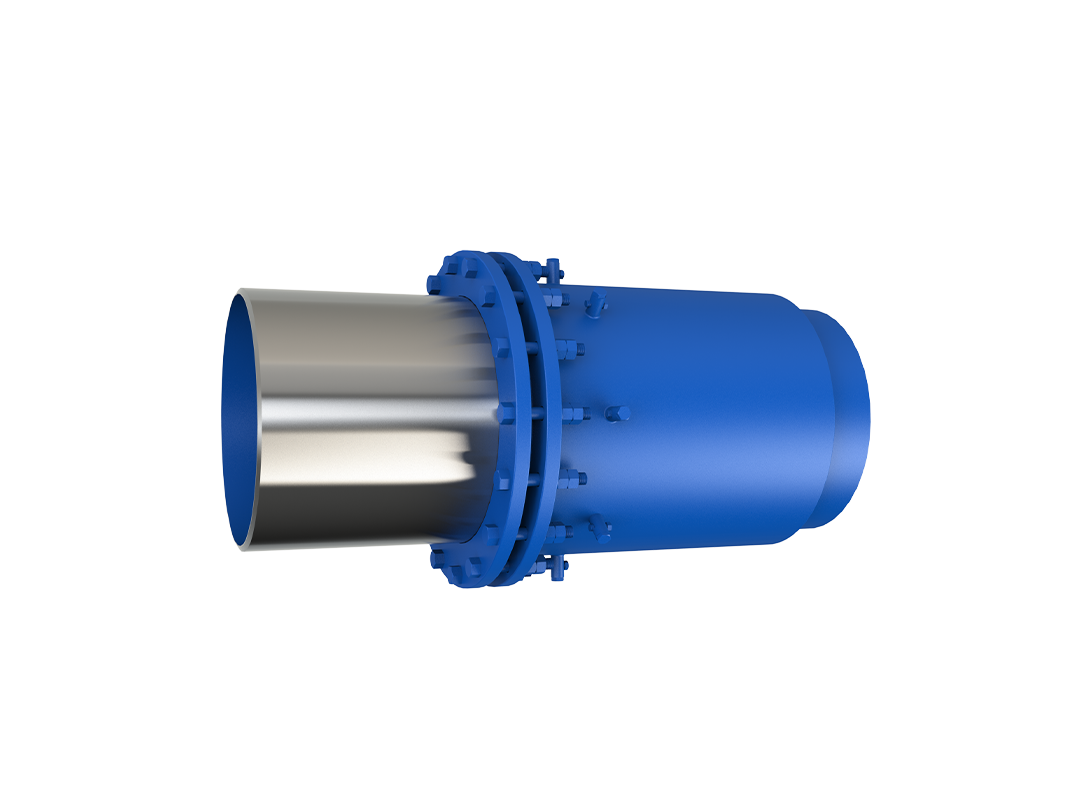

Filled-type sleeve compensator

Classification: Product

Product Details

The injected filling sleeve compensator is an effective device for addressing thermal expansion and contraction issues in pipeline systems. Its working principle is based on a sleeve structure, which allows for relative displacement of the sleeve by filling it with special sealing materials. This effectively absorbs the expansion and contraction of the pipeline caused by temperature changes, ensuring the stable operation of the pipeline system.

This compensator has significant advantages. In terms of sealing performance, the specially designed sealing materials and precise structural design ensure good sealing under different working conditions, eliminating the risk of medium leakage. It has strong compressive strength and can withstand high-pressure pipeline environments, making it widely applicable. Installation and maintenance are also relatively convenient, requiring no complex operations, thus reducing construction and later maintenance costs.

In many fields such as heating networks, chemical pipelines, and oil transportation, the injected filling sleeve compensator plays an important role. Whether it is temperature compensation for long-distance pipelines or pipeline displacement adjustment under complex working conditions, it can provide reliable assurance for the safe and efficient operation of pipeline systems with its excellent performance, extend the service life of pipelines, and reduce the frequency of failures.

Key words:Filled-type sleeve compensator

Previous: No more!

The next one: Non-metallic circular compensator

Filled-type sleeve compensator

The filled sleeve compensator is an effective device in pipeline systems to address the issues of thermal expansion and contraction. Its working principle is based on a sleeve structure, which allows for relative displacement of the sleeve when the pipeline expands or contracts due to temperature changes, by filling it with special sealing materials. This effectively absorbs the expansion and contraction of the pipeline, ensuring the stable operation of the pipeline system.

Related Products

Product inquiry

Leave the information you want to consult and we will contact you as soon as possible.