Company Profile

Wuhan Yongtai Corrugated Pipe Co., Ltd., established in 2001, is a modern technological industrial pipeline product processing and manufacturing enterprise integrating scientific research and development, high-tech CNC processing, and scientific management. It specializes in producing various metal corrugated expansion joints, stainless steel flexible metal hoses, expansion joints, pipe supports, thermal insulation pipe supports, cold insulation pipe supports, low-friction pipe supports, swing supports, spring hangers, non-metallic expansion joints, and other pipeline fittings. The company covers an area of 50,000 square meters and has a building area of 40,000 square meters. It currently has more than 120 employees, including more than 20 engineering and technical personnel and more than 10 professionals with intermediate and senior professional titles. The company owns more than 200 sets of professional production equipment and testing devices.

In early 2002, our company passed the IS09001:2000 quality system certification and subsequently obtained the manufacturing license for special equipment for pressure pipeline components. It also obtained product conformity certificates in accordance with GB/T12777-1999 "General Technical Conditions for Metal Corrugated Expansion Joints", GB/T14525-1993 "General Technical Conditions for Corrugated Metal Flexible Hoses", and other standards. For many years, it has continuously won the provincial and municipal titles of "Honoring Contracts and Keeping Promises" and "High-Quality Products", and has obtained AAA-level credit enterprise certification. It has become a member unit of organizations such as the Pressure Vessel Branch of the Chinese Society of Mechanical Engineering and the Expansion Joint Branch of the China Petroleum and Petrochemical Equipment Industry Association.

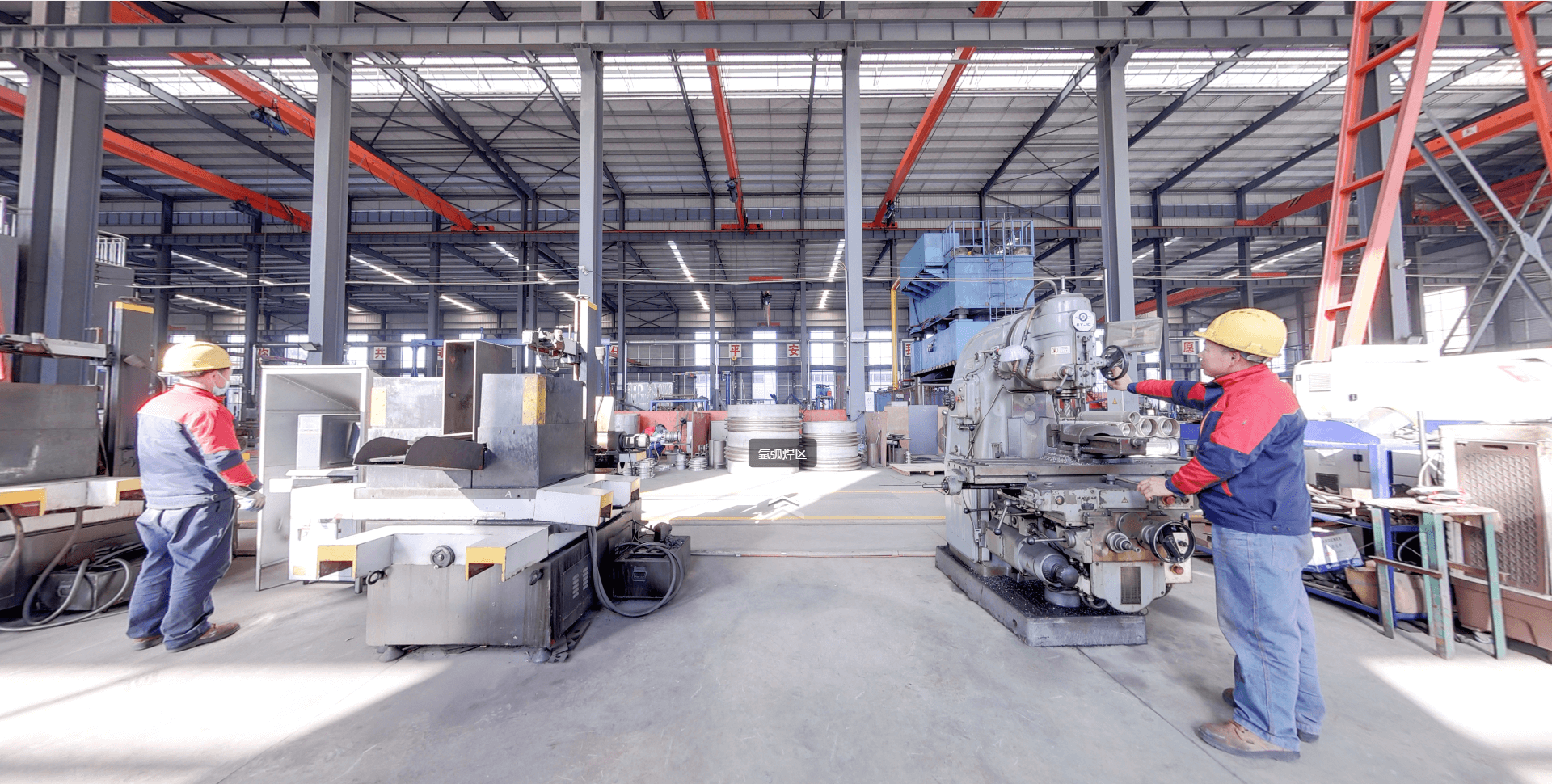

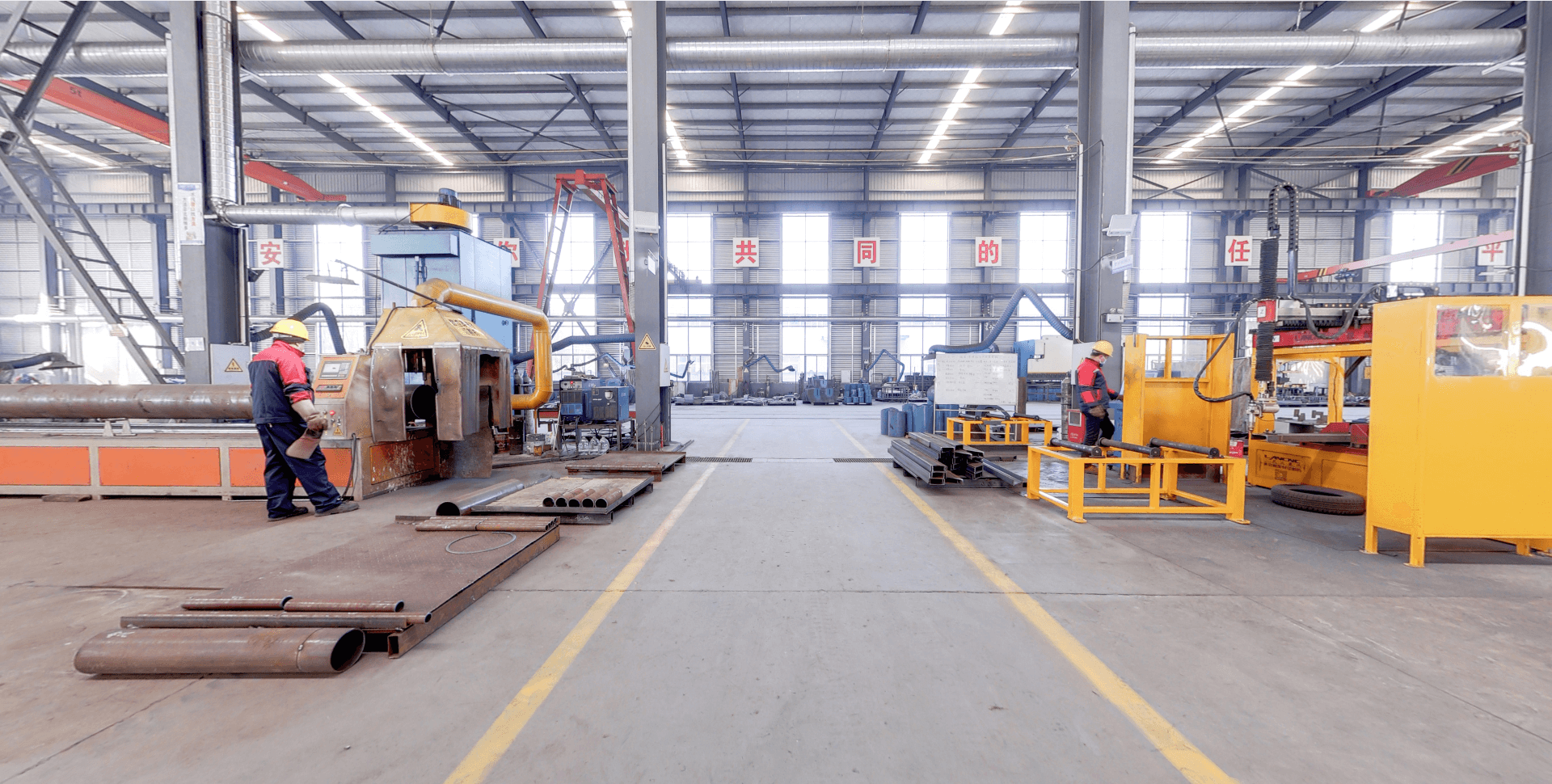

With the continuous development and expansion of the company's production scale, our company has a complete set of advanced and professional production and testing equipment: including 5 corrugated pipe hydraulic forming equipment; 7 shearing machines and rolling machines of different specifications and applications; more than 40 sets of submerged arc welding machines, CO2 gas shielded welding machines, thin-walled argon arc welding longitudinal seam automatic welding machines, argon arc welding machines, electric welding machines, and cutting machines; and 4 sets of airtight test and hydraulic test devices. In addition, there are more than 20 sets of general-purpose mechanical equipment.

In the long-term production process, our company has collected a large amount of data and accumulated rich production experience through production practice, experimental research, and computer software design. We have compiled scientific and advanced production process documents, expansion joint process quality standards, corrugated metal flexible hose process quality standards, and metal corrugated pipe welding and inspection process regulations, etc. This ensures that each process and step of product production is under controlled conditions that meet standards, ensuring the stability and quality of product production. At the same time, the company designs, manufactures, and accepts products according to standards such as "General Technical Conditions for Metal Corrugated Expansion Joints" (GB/T12777-1999), "American Expansion Joint Manufacturers Association Standard" (EJMA), and "Pressure Vessel Corrugated Expansion Joints" (GB/T16749-1997). Advanced computer software is used to optimize the design of the corrugated pipe, ensuring the optimal matching of the main technical performance parameters of the expansion joint to fully meet the user's on-site operating conditions.

Currently, our company can mass-produce more than 20 types of expansion joints, including various types and specifications of circular metal expansion joints and rectangular metal expansion joints; and various specifications of circular and rectangular non-metallic expansion joints. In addition, it can also produce various specifications of stainless steel corrugated metal flexible hoses, various types and specifications of polytetrafluoroethylene pipe plane sliding and guiding brackets, and various types of spring supports and hangers, which can meet user needs according to their operating conditions.

Our company always adheres to the principle of "seeking development through scientific research and survival through quality." While striving to improve the company's independent research and development and innovation capabilities, we insist on putting product design and manufacturing quality first. First, in the key links of the production process, we have professional and high-level personnel management and control, strictly following the ISO9001-2000 quality management system procedures and standards to control the quality of products in each process. Especially in the quality inspection link, a series of measurement technical procedures and inspection procedures have been formulated. A three-level inspection system is implemented in each process, from the re-inspection of raw materials to the factory inspection of products. Strict records and inspections are carried out for special and key processes in the production process, and samples are sent to the municipal quality supervision and inspection bureau for re-inspection and confirmation every month, thus ensuring the design and manufacturing quality of the products.

Because of our company's good social image, good reputation, strong Technology, and strong production capacity, high-quality and low-priced products, and attentive pre-sale and After-sale Service, our various products have been recommended and selected for use by numerous domestic design research institutes, the China Engineering Construction Standardization Association, and users in various industries. Products are used in almost every province, city, and autonomous region in China, widely used in ① iron and steel smelting, thermal energy, gas (steam) supply, and hot and cold air systems in the metallurgical industry; ② generator sets, coal powder systems, steam networks, and hot and cold air systems in the power industry; ③ regeneration reactions, energy recovery, catalytic cracking units, and oil pipelines in the petrochemical industry; ④ steam and hot water networks for urban heating; and ⑤ coal mining, automobiles, gas heating, aluminum smelting, food, and mechanical manufacturing industries. Products have also been exported to India, Indonesia, Iran, and Sudan. The reliable quality and good performance of these products have won praise and acclaim from a large number of new and old customers, and the market share has been continuously consolidated and expanded.

At the same time, our company has established more than 20 offices in major and medium-sized cities across the country to promptly grasp and understand user information and requirements, and promptly track product usage, providing users with the fastest and most convenient high-quality service.

General Manager Huang Yonghe and all his colleagues will continue to provide high-quality service to our new and old customers. We warmly welcome users to visit and guide our company.