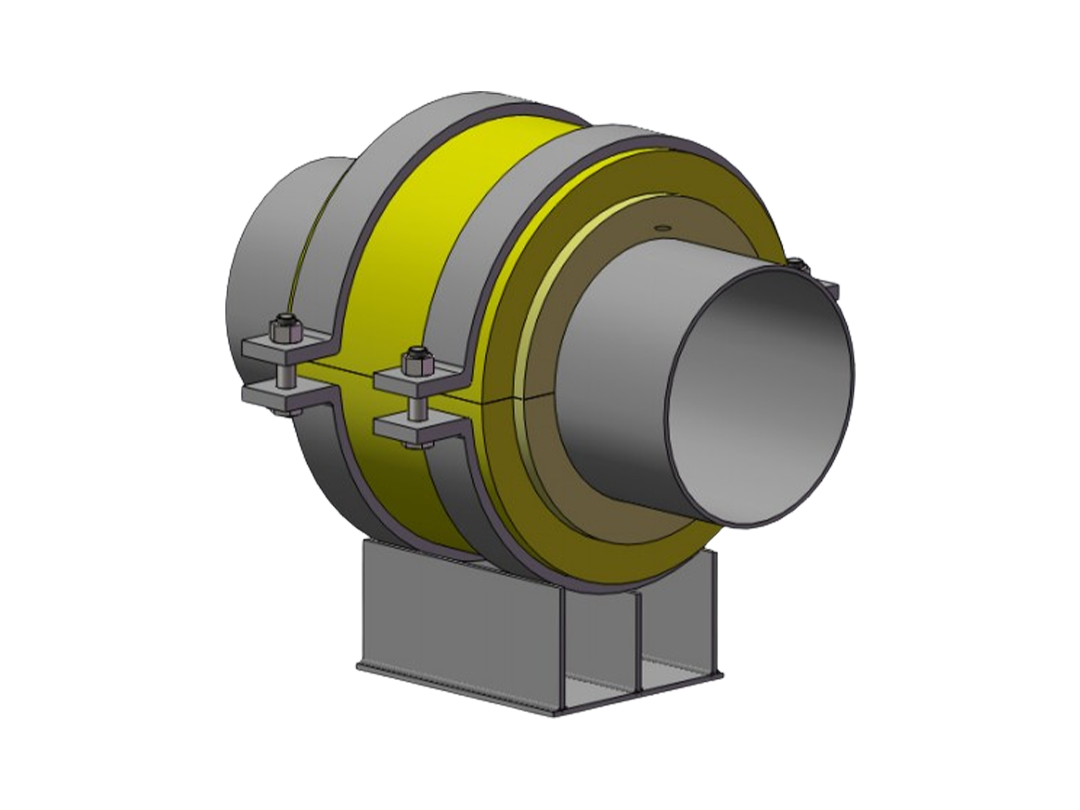

Pipe support

Classification: Low Friction

Product Details

The design and selection of the pipe support structure is an important component of pipeline system design. In addition to supporting the weight of the pipeline, specially designed pipe supports can balance the forces acting on the pipeline system, limit pipeline displacement, and absorb vibrations. When designing a pipeline system, correctly selecting and arranging structurally reasonable pipe supports can improve the stress release of the pipeline and the forces acting on the pipe rack, ensuring the safe operation of the pipeline system and extending its service life.

To improve the efficiency of pipeline design and accelerate the speed of pipeline installation, the standardization and specialized production of pipe support structures are imperative. To this end, our company organizes relevant professionals to collaborate with domestic design and research units in the petrochemical, electric power, and other industries. Based on the characteristics of pipeline transportation and the requirements for pipeline systems in petrochemical, electric power, metallurgy, and thermal network projects, we have designed a series of pipe support products for various processes, heating, cooling, and other pipeline installation designs.

Our company will continuously improve the design of pipe support structures and periodically revise the product series to meet the process requirements of various pipeline supports.

Our company can design special-purpose pipe supports for a wide range of users, but users need to provide usage conditions, specific sizes, and

pipeline layout diagrams.

Our company's series of pipe support products consists of thermal insulation pipe supports, cold insulation pipe supports, ordinary pipe supports, hangers, and other components. The product classification and model descriptions are as follows:

1. Product Classification

1. Thermal Insulation Pipe Support (PHK type): Sliding pipe support, guiding pipe support, fixed pipe support;

2. Cold Insulation Pipe Support (DCK type): Sliding pipe support, guiding pipe support, fixed pipe support;

3. Thermal Insulation and Cold Insulation Dual-purpose Pipe Support (PDK type);

4. Ordinary Pipe Support (GAK, GAH type): Clamp type pipe support, welded type pipe support.

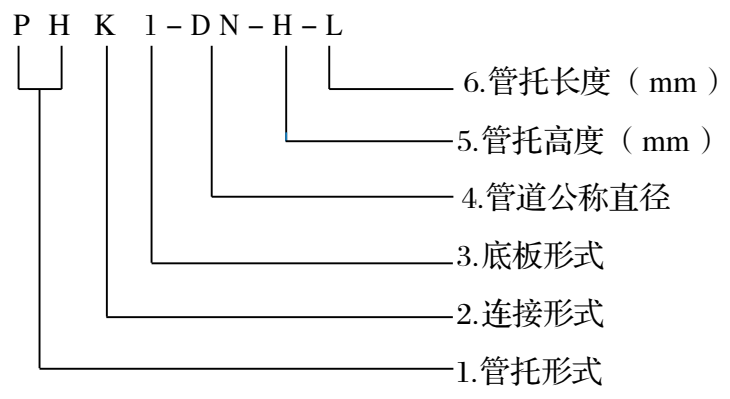

2. Model Description

1. Pipe Support Type

PH---Thermal Insulation Pipe Support

DC---Cold Insulation Pipe Support

PD---Thermal Insulation and Cold Insulation Dual-purpose Pipe Support

GA---Ordinary Pipe Support

2. Connection Type

K---Clamp Type

H---Welded Type

3. Base Plate Type

1---Sliding Type (PTFE and stainless steel, friction coefficient 0.06)

2---Guiding Type (PTFE and stainless steel, friction coefficient 0.06)

3---Sliding Type (PTFE and PTFE, friction coefficient 0.04)

4---Guiding Type (PTFE and PTFE, friction coefficient 0.04)

5---Sliding Type (carbon steel and carbon steel, friction coefficient 0.3)

6---Guiding Type (carbon steel and carbon steel, friction coefficient 0.3)

7---Welded Fixed Type

8---Limit Stop Fixed Type

4. Nominal Diameter

The nominal diameter of the pipeline is divided into two major series: Series A and Series B. Series A is in imperial specifications, while Series B is in metric specifications. When the pipeline diameter is in imperial specifications, it is measured in inches; when the pipeline diameter is in metric specifications, it is measured in millimeters.

5. Pipe Support Height: Measured in mm.

6. Pipe Support Length: Measured in mm.

3. Selection Example

For a DN150 steam pipeline, the design adopts a pipe support height of 150mm and a length of 300mm, with the pipe support base plate made of PTFE and stainless steel for sliding pipe support.

When the pipeline uses metric specifications, the pipe support model is represented as PHK1-150-150-300;

When the pipeline uses imperial specifications, the pipe support model is represented as PHK1-6"-150-300.

Key words:Pipe support

Previous: No more!

The next one: No more!

Pipe support

The design and selection of the pipe support structure is an important component in the design of pipeline systems. In addition to supporting the weight of the pipeline, specially designed pipe supports can balance the forces acting on the pipeline, limit pipeline displacement, and absorb vibrations. When designing a pipeline system, correctly selecting and arranging structurally reasonable pipe supports can improve the stress release of the pipeline and the forces acting on the pipe rack, ensuring the safe operation of the pipeline system and extending its service life.

Related Products

Product inquiry

Leave the information you want to consult and we will contact you as soon as possible.