Variable spring support

Classification: Spring Hanger

Product Details

Variable spring hangers are used to compensate for vertical displacement caused by thermal expansion of pipelines. They are used in locations where there is vertical displacement at the support points and the load-bearing capacity of the hanger changes to a certain extent with the vertical displacement of the pipeline, with a load variation rate generally not exceeding 25%.

Variable spring hangers use cylindrical helical springs, and the deformation of the spring is linearly related to the support load.

This sample compiles commonly used VS series variable spring hangers (JB/T 8130.2) T-type variable spring hangers (Northwest Electric Power Design Institute standard) for user selection.

A selection of variable spring hanger types

Select the type of hanger based on the structure of the root beam of the hanger and the spatial position of the pipeline (the type in parentheses is T-type variable spring hanger).

1. A, B (T1), C (T2) type hangers are suspended types, with the upper end of the hanger connected to the root beam by a rod, and the lower end connected to the pipeline by a nut and a hanger rod.

2. D (T3), E type hangers are resting types, with the base resting on a beam or floor, and the pipeline suspended below by a hanger rod.

3. F type (T4) brackets are supporting types, placed on a foundation plane or steel structure, with the top load plate supporting the pipeline. F type is divided into ordinary type (FⅠ) and roller type (FⅡ). When the horizontal displacement of the pipeline exceeds 6mm, it is recommended to choose FⅡ type.

4. When the spring hanger cannot be directly suspended above the pipeline or there is not enough height, and the pipeline has horizontal displacement and the load exceeds the series range, G (T5) type hangers can be used. If G (T5) type hangers are used, the selection of hanger number should be based on half of the calculated working load.

B design selection of variable spring hangers

1. General principles

Select the hanger number based on the calculated working load during pipeline operation (including pipeline, materials, valves, insulation materials, pipeline accessories, etc.), working displacement, and displacement direction.

1.1 First, determine the working displacement range based on the working displacement.

1.2 If the pipeline displacement direction is upward, find the working load between the centerline and the upper thick line in the table, and then look down according to the working displacement to find the corresponding installation load. The scale value of the working displacement is listed on the left side of the table according to different displacement ranges.

1.3 If the pipeline displacement direction is downward, find the working load between the centerline and the lower line in the table, and then look up according to the working displacement to find the corresponding installation load. The scale value of the working displacement is listed on the left side of the table according to different displacement ranges.

1.4 When selecting, regardless of whether the pipeline displacement is upward or downward, both the working load and installation load must be between the upper and lower thick lines in Table 1-1, and the load variation rate must not exceed 25%.

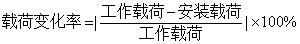

2 Load variation rate

In the formula:

When the pipeline displacement is upward, installation load = working load + displacement × spring stiffness

When the pipeline displacement is downward, installation load = working load - displacement × spring stiffness

The load variation rate of variable spring hangers generally does not exceed 25%, but T-type variable spring hangers have three options of 20%, 25%, and 35% based on usage conditions.

The installation load and working load obtained from the table should be between the upper and lower thick lines, but when the displacement is small, it may also appear between the centerline and a certain thick line.

After obtaining the installation load and working load, the load variation rate must be verified according to the above formula. If the load variation rate exceeds 25%, a larger working displacement range can be selected, and the corresponding installation load can be found. If the requirement of load variation rate ≤ 25% cannot be met, consider selecting constant force spring hangers.

2. Design selection examples are provided in the following two sections.

C installation and adjustment of variable spring hangers

1. A type

Screw the root bolts on the beam into the screw holes of the hanger's top plate and lock them with nuts. Then connect the lower end of the nut to the threaded upper end of the pipeline hanger rod. Rotate the nut to position the indicator plate at the corresponding scale of the hanger installation load to ensure that the positioning block can be easily removed (but do not remove the positioning block yet, wait until before operation), and then lock it with a nut.

2. B (T1) type, C (T2) type (the type in parentheses is T-type variable spring hanger, the same below)

Both are connected by an upper hanger rod and a hanger ear, hanging under the beam, and the other installation methods are the same as A type.

3. D type (T3) type

Fix the hanger to the beam or floor with bolts, and the hanger rod passes through the hanger body and connects to the pipeline. Rotate the top nut to adjust the installation load, and after completion, lock the adjustment nut with a nut. The other installation methods are the same as A type.

4. E type

Fix the hanger to the beam or floor with bolts, and the other installation methods are the same as A type.

5. F type (T4) type

Fix the bracket to the beam or floor with bolts, and the bracket supports the bottom of the horizontal pipe or elbow. The installation height selected for F type brackets in engineering design.

5.1 When the pipeline displacement is upward, the installation height of the bracket is L average.

5.2 When the pipeline displacement is downward, the installation height of the bracket is L average + displacement.

5.3 For brackets with positioning blocks, the load column should be rotated first to reach the installation height before installation. If there is a discrepancy between the installation height and the actual support height on site, the load column can be rotated for fine-tuning. The adjustment range of VS series spring hangers is noted in Table 1-6.

6.G type (T5) type

The hanging rod in the screw-in nut is connected to the upper beam plate, and the pipeline is placed in the middle position of the hanger channel steel. Symmetrically rotate the screw nut to adjust the indicator board to the position corresponding to the installation load, and lock it with the nut.

7. The positioning blocks are manufactured by the factory according to the installation load of the spring hanger. The upper and lower blocks are placed on the upper and lower parts of the indicator board, respectively, to fix the displacement indicator board of the hanger at the position corresponding to the installation load, ensuring the rigidity of the hanger.

8. When adjusting the hanger, all hangers installed on the same pipeline should be adjusted simultaneously, so that each hanger is in the installation load state required by the design. At this time, the indicator board and the upper and lower positioning blocks are not under stress, making it easy to remove the upper and lower positioning blocks.

9. After the pipeline is cleaned and pressure tested, the upper and lower positioning blocks of each hanger can be removed, and the pipeline can then be put into operation.

10. When the pipeline starts to operate, first check whether all the positioning blocks of each hanger have been removed, and then check whether there is any jamming phenomenon in the process of the indicator board moving from the installation load to the working load corresponding position. After normal operation, observe whether the working load and displacement of the hanger are correct. After stopping operation, check the reset status of each hanger.

Key words:Variable spring support

Previous: No more!

The next one: No more!

Variable spring support

Variable spring hangers are used to compensate for vertical displacement caused by thermal expansion of pipes. They are used in locations where there is vertical displacement at the support points and where the load-bearing capacity of the hangers changes to a certain extent with the vertical displacement of the pipes. The load variation rate is generally not greater than 25%.

Related Products

Product inquiry

Leave the information you want to consult and we will contact you as soon as possible.